EXTERNAL BROACHING PART PREPARATION

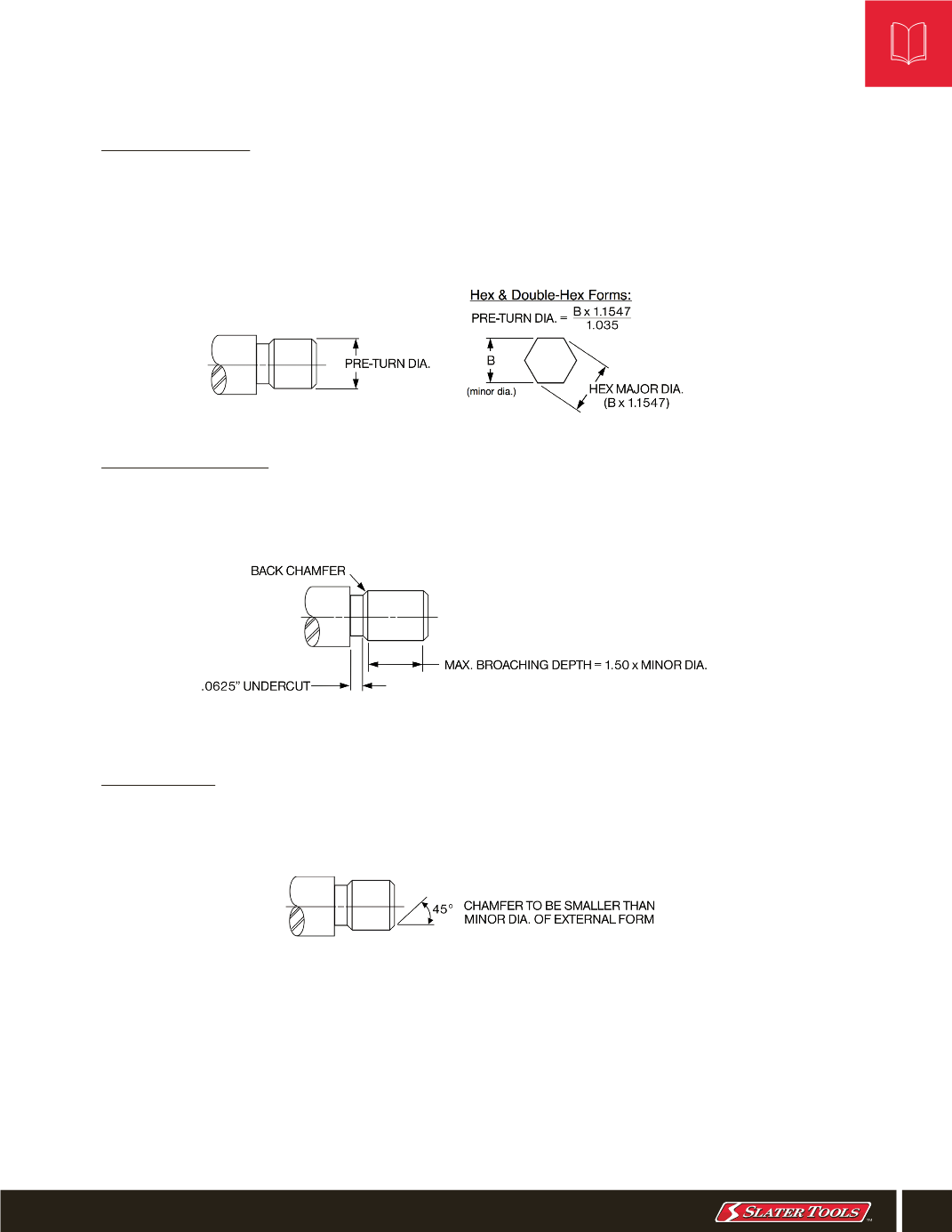

Pre-Turn Diameter:

• Pre-turning the diameter of the workpiece is required for external broaching.

• The pre-turned diameter must be smaller than the major diameter of the broach.

• It is recommended to turn the workpiece diameter to the smallest allowable diameter so the

broach will clear on the major diameter. Allowing for more clearance will reduce the required

broaching pressure and increase tool life.

• See below formulas for recommended pre-turn diameters of hex and double-hex forms.

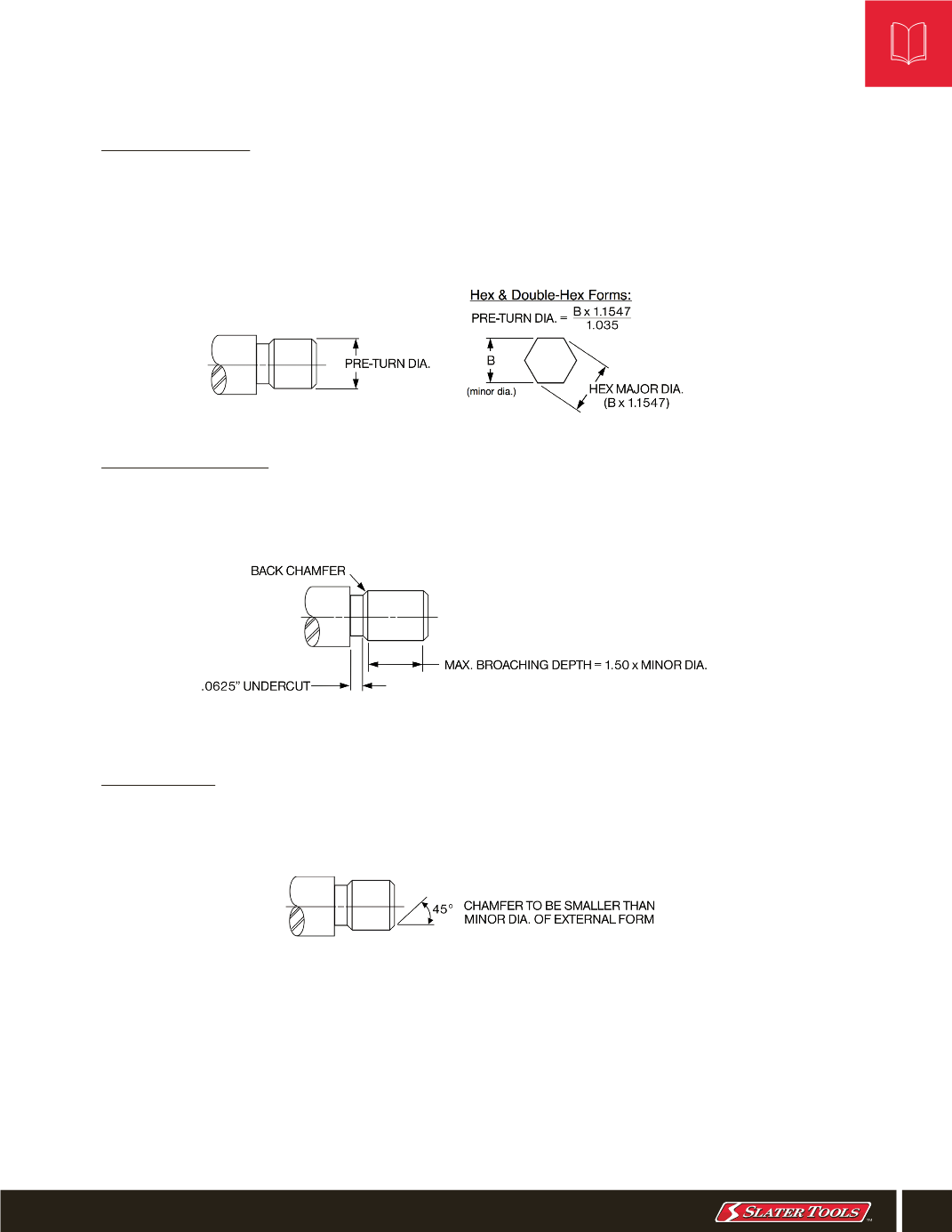

External Form Depth:

• Maximum recommended broach depth is 1.5 x minor diameter of form.

• A back-chamfer or undercut will allow chips to break cleanly. The undercut should be a

approximately .0625” wide.

Lead Chamfer:

• A 45° lead chamfer must be provided for successful external rotary broaching, going from

the minor diameter to the major diameter of the form.

35

TECHNICAL SUPPORT

PHONE:

(586) 465-5000

•

FAX:

(586) 465-3030