PART PREPARATION GUIDE

INTERNAL BROACHING PART PREPARATION

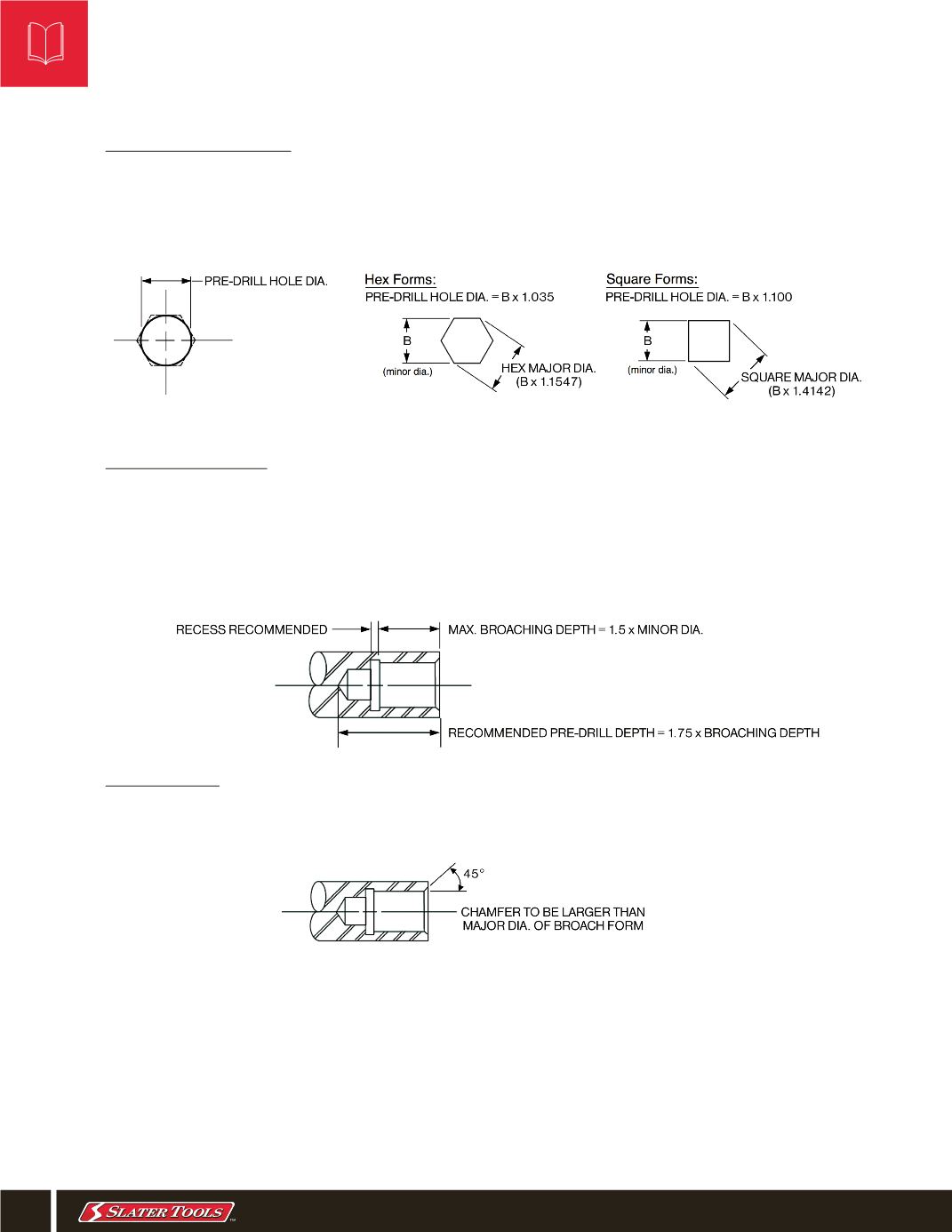

Pre-Drill Hole Diameter:

• A pre-drill hole is required for internal broaching.

• The pre-drill hole must be at least equal to the minor diameter of the broach. It is strongly

recommended to open the hole diameter larger than the minor diameter.

• See below formulas for recommended pre-drill hole diameters of hex and square forms.

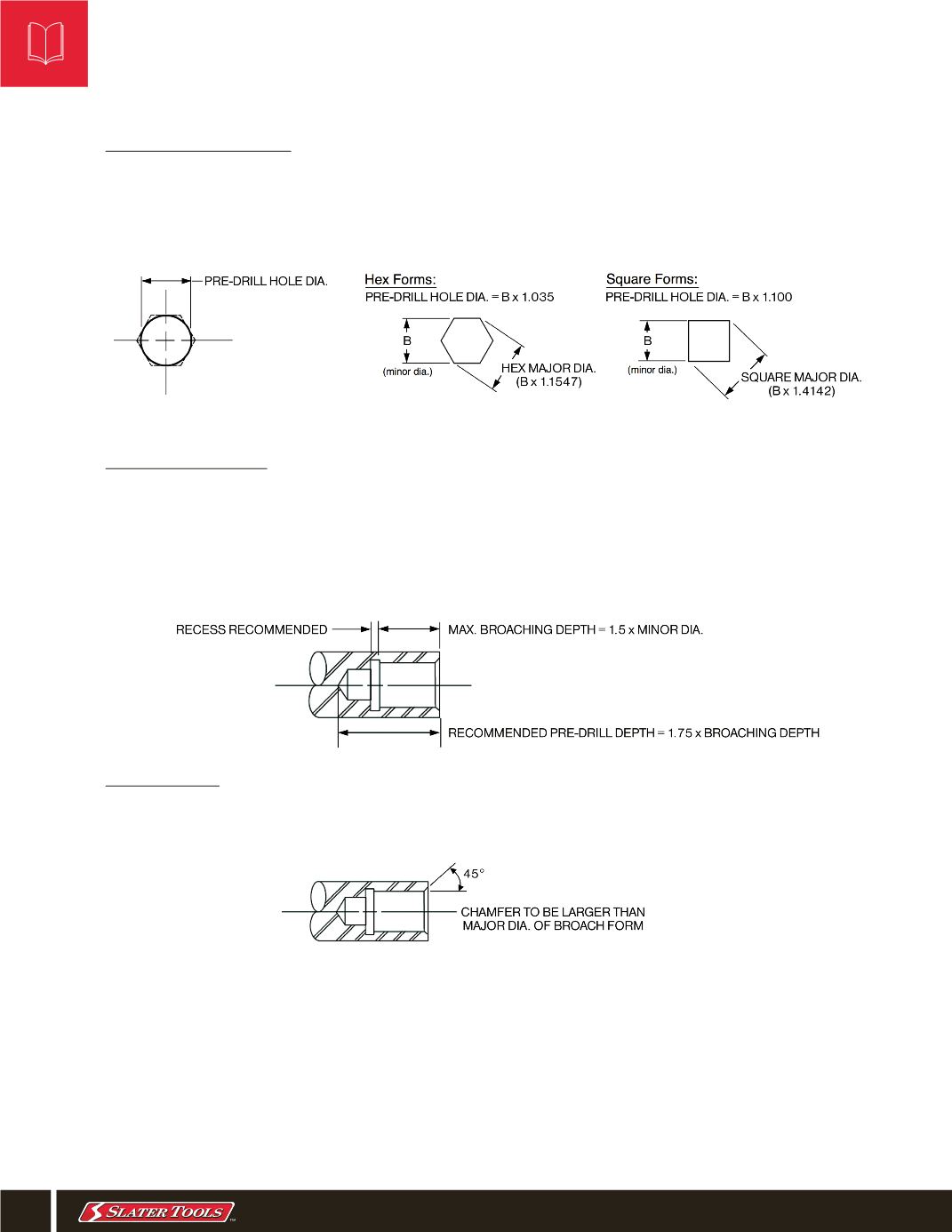

Pre-Drill Hole Depth:

• The depth of the pre-drill hole must be greater than the broaching depth to allow for chips to

accumulate and avoid excess packing.

• If chips must be removed after broaching, it can be done with a drill or boring tool. A recess at

the bottom of the pre-drill will allow the chips to break cleanly. The recess diameter should be

larger than the major diameter of the broach.

• It is recommended to have a pre-drill depth of 1.75 x depth of broached area.

Lead Chamfer:

• A 45° lead chamfer must be provided for successful internal rotary broaching, going from the

major diameter to the minor diameter of the form.

34

TECHNICAL SUPPORT

•

EMAIL: