External Hexagon Broaches

External hexagon rotary broaches are offered in standard sizes and can also be made per your print. Various materials, coatings and resharpening are also offered on any of Slater Tools' external rotary broaches.

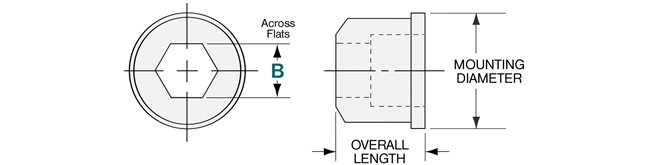

MOUNTING DIAMETER: 1.5748"

OVERALL LENGTH: 1.00”

ENGLISH SIZES

| Nominal Size (in) | B | Part # |

|---|---|---|

| 1/4" External Hex Broach | .244 | 1462-244 |

| 9/32" External Hex Broach | .275 | 1462-275 |

| 5/16" External Hex Broach | .305 | 1462-305 |

| 11/32" External Hex Broach | .336 | 1462-336 |

| 3/8" External Hex Broach | .367 | 1462-367 |

| 13/32" External Hex Broach | .397 | 1462-397 |

| 7/16" External Hex Broach | .428 | 1462-428 |

| 15/32" External Hex Broach | .463 | 1462-463 |

| 1/2" External Hex Broach | .489 | 1462-489 |

| 17/32" External Hex Broach | .520 | 1462-520 |

| 9/16" External Hex Broach | .551 | 1462-551 |

| 19/32" External Hex Broach | .582 | 1462-582 |

| 5/8" External Hex Broach | .612 | 1462-612 |

| 21/32" External Hex Broach | .643 | 1462-643 |

| 11/16" External Hex Broach | .674 | 1462-674 |

| 23/32" External Hex Broach | .705 | 1462-705 |

| 3/4" External Hex Broach | .736 | 1462-736 |

METRIC SIZES

| Nominal Size (mm) | B | Part # |

|---|---|---|

| 6mm External Hex Broach | .228 | 1462-228 |

| 7mm External Hex Broach | .267 | 1462-267 |

| 8mm External Hex Broach | .306 | 1462-306 |

| 9mm External Hex Broach | .346 | 1462-346 |

| 10mm External Hex Broach | .385 | 1462-385 |

| 11mm External Hex Broach | .424 | 1462-424 |

| 12mm External Hex Broach | .462 | 1462-462 |

| 13mm External Hex Broach | .501 | 1462-501 |

| 14mm External Hex Broach | .540 | 1462-540 |

| 15mm External Hex Broach | .580 | 1462-580 |

| 16mm External Hex Broach | .619 | 1462-619 |

| 17mm External Hex Broach | .659 | 1462-659 |

| 18mm External Hex Broach | .698 | 1462-698 |

| 19mm External Hex Broach | .737 | 1462-737 |

COATING OPTIONS

Titanium Nitride (TiN)

TiN is a gold colored PVD coating made of exceptionally hard ceramic material that improves lubricity, increases hardness and enhances abrasive wear resistance leading to increased broach tool life.

Titanium Carbonitride (TiCN)

TiCN is a purple-gray colored PVD coating formed by the addition of carbon to the TiN formula. The elevated hardness and low residual stress lead to excellent abrasive wear resistance. TiCN coating also increases lubricity of the broach and performs well under high load conditions. TiCN is commonly used in medical and aerospace applications broaching small forms in stainless steel and titanium materials.

Titanium Aluminum Nitride (TiAIN)

TiAlN is a dark gray colored PVD coating that can be used in high temperature conditions and for better lubricity. Harder than TiN, TiAlN has excellent abrasive wear resistance and is used successfully to broach many materials such as titanium, aluminum, stainless steels, and alloy steels.

MATERIAL OPTIONS

M2 High Speed Steel

M2 is a molybdenum based high speed steel that is characterized by abrasion resistance, toughness and good red hardness. Slater Tools' hardened M2 broaches have an ideal balance of bending strength, toughness and wear resistance. M2 is used in a wide range of rotary broaching applications and is suitable for any broachable material.

PM M4 High Speed Steel

PM M4 is a molybdenum-tungsten high speed steel, which is produced with a very consistent and refined structure. This structure gives PM M4 broaches several enhanced properties including improved toughness and better wear resistance. This material is good for stainless steel and titanium applications for decreased wear.

OTHER CUSTOM OPTIONS

- Custom Overall Lengths Available

- Custom dimensions

- MICRO forms

- Corner radius

- Mounting slot can be aligned with form (for holding orientation)

External Broaching Part Preparation

Pre-Turn Diameter:

- Pre-turning the diameter of the workpiece is required for external broaching.

- The pre-turned diameter must be smaller than the major diameter of the broach.

- It is recommended to turn the workpiece diameter to the smallest allowable diameter so the broach will clear on the major diameter. Allowing for more clearance will reduce the required broaching pressure and increase tool life.

- See below formulas for recommended pre-turn diameters of hex and double-hex forms.

External Form Depth:

- Maximum recommended broach depth is 1.5 x minor diameter of form.

- A back-chamfer or undercut will allow chips to break cleanly. The undercut should be approximately .0625" wide.

Lead Chamfer:

- A 45° lead chamfer must be provided for successful external rotary broaching, going from the minor diameter to the major diameter of the form.

Speeds and Feeds

Speeds and feed rates for rotary broaching will depend on the material you are broaching and size form. Please refer to the Slater Tools Speeds and Feeds Chart.

Close

Menu

Close

Menu

.jpg)

.jpg)